Liquid Nitrogen Generator

Overview

Liquid nitrogen generators produce liquid nitrogen (LN2) through various methods, including cryogenic distillation, pressure swing adsorption (PSA), and membrane separation.

Types

Cryogenic Distillation Generators

Pressure Swing Adsorption (PSA) Generators

Membrane Separation Generators

Cryogenic Expansion Generators

Stirling Cryogenic Generators

Principle

Air is compressed and filtered.

Air is cooled to extremely low temperatures.

Nitrogen is separated and liquefied.

LN2 is stored in a Dewar flask or tank.

Applications

Cryopreservation and cryostorage

Medical research and healthcare

Food freezing and packaging

Material testing and analysis

Aerospace and defense

Electronics manufacturing

Laser cutting and welding

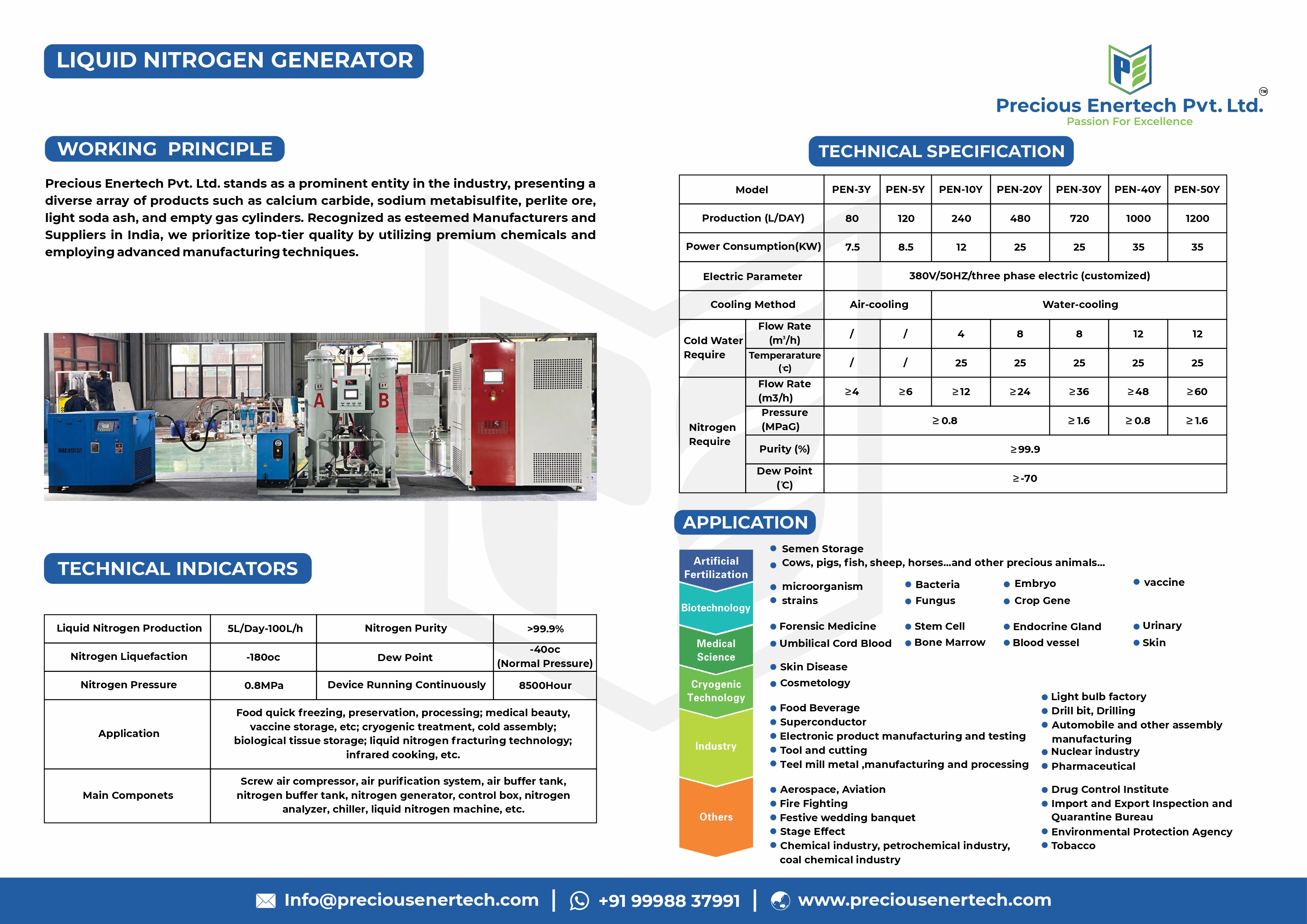

Specifications

Capacity: 1-100 liters/hour

Purity: 99.999%

Temperature: -196°C

Pressure: 10-30 bar

Power consumption: 1-50 kW

Features

Automated control systems

Cryogenic cooling systems

Insulation and vacuum jacketing

LN2 storage and transportation

Safety features (e.g., pressure relief valves)

Certifications

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

ASME (American Society of Mechanical Engineers)

CE (Conformité Européene)

UL (Underwriters Laboratories)

Benefits

High-purity LN2 production

Low operating costs

Compact and lightweight design

Fast startup and shutdown times

Reliable and consistent performance

Challenges

High energy consumption

Complex maintenance requirements

Limited scalability

Safety concerns (e.g., cryogenic temperatures)

High upfront costs

Overview

Liquid nitrogen generators produce liquid nitrogen (LN2) through various methods, including cryogenic distillation, pressure swing adsorption (PSA), and membrane separation.

Types

Cryogenic Distillation Generators

Pressure Swing Adsorption (PSA) Generators

Membrane Separation Generators

Cryogenic Expansion Generators

Stirling Cryogenic Generators

Principle

Air is compressed and filtered.

Air is cooled to extremely low temperatures.

Nitrogen is separated and liquefied.

LN2 is stored in a Dewar flask or tank.

Applications

Cryopreservation and cryostorage

Medical research and healthcare

Food freezing and packaging

Material testing and analysis

Aerospace and defense

Electronics manufacturing

Laser cutting and welding

Specifications

Capacity: 1-100 liters/hour

Purity: 99.999%

Temperature: -196°C

Pressure: 10-30 bar

Power consumption: 1-50 kW

Features

Automated control systems

Cryogenic cooling systems

Insulation and vacuum jacketing

LN2 storage and transportation

Safety features (e.g., pressure relief valves)

Certifications

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

ASME (American Society of Mechanical Engineers)

CE (Conformité Européene)

UL (Underwriters Laboratories)

Benefits

High-purity LN2 production

Low operating costs

Compact and lightweight design

Fast startup and shutdown times

Reliable and consistent performance

Challenges

High energy consumption

Complex maintenance requirements

Limited scalability

Safety concerns (e.g., cryogenic temperatures)

High upfront costs