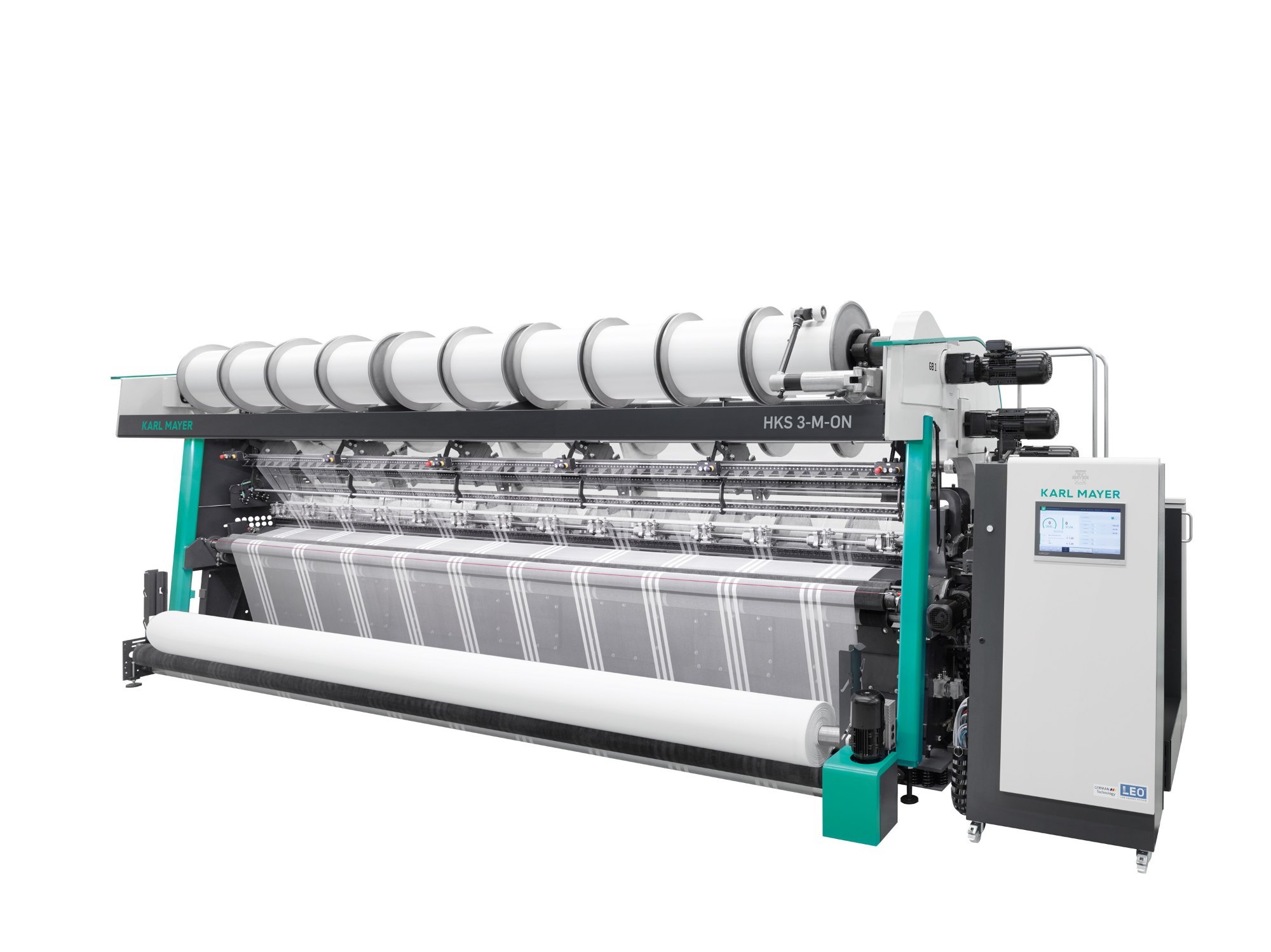

Wrap Knitting Machines

Introduction

Wrap knitting machines are warp knitting machines used for producing fabrics by interlacing yarns in a lengthwise (warp) direction.

They are different from weft knitting machines, where yarns run crosswise.

Commonly used for making lace, nets, mesh fabrics, and industrial textiles.

Types

Tricot Machines

Raschel Machines

Milanese Machines

Main Parts

Warp Beam – supplies yarns in parallel form.

Guide Bar – directs yarns into specific patterns.

Needle Bar – contains latch or compound needles for loop formation.

Sinker Bar – helps in fabric formation and loop holding.

Take-up Mechanism – rolls the fabric after formation.

Working Principle

Yarns are unwound from warp beams.

Guide bars move yarns around needles to form loops.

Loops interlock in the warp direction.

Pattern depends on the movement of guide bars (controlled by cams or electronic systems).

Features

High speed production (thousands of courses per minute).

Can process synthetic, natural, and blended yarns.

Produces stable and strong fabrics compared to weft knitting.

Capable of intricate designs and patterns.

Applications

Apparel: Lingerie, sportswear, swimwear.

Home textiles: Curtains, nets, lace fabrics.

Industrial uses: Coated fabrics, automotive textiles, geotextiles.

Medical textiles: Bandages, compression fabrics.

Advantages

High productivity and efficiency.

Fabrics are dimensionally stable and do not ladder easily.

Wide variety of designs possible.

Suitable for technical and industrial textiles.

Limitations

Machines are expensive.

Fabric designs depend on guide bar movement (less flexible than weft knitting).

Requires skilled operation and maintenance.

Introduction

Wrap knitting machines are warp knitting machines used for producing fabrics by interlacing yarns in a lengthwise (warp) direction.

They are different from weft knitting machines, where yarns run crosswise.

Commonly used for making lace, nets, mesh fabrics, and industrial textiles.

Types

Tricot Machines

Raschel Machines

Milanese Machines

Main Parts

Warp Beam – supplies yarns in parallel form.

Guide Bar – directs yarns into specific patterns.

Needle Bar – contains latch or compound needles for loop formation.

Sinker Bar – helps in fabric formation and loop holding.

Take-up Mechanism – rolls the fabric after formation.

Working Principle

Yarns are unwound from warp beams.

Guide bars move yarns around needles to form loops.

Loops interlock in the warp direction.

Pattern depends on the movement of guide bars (controlled by cams or electronic systems).

Features

High speed production (thousands of courses per minute).

Can process synthetic, natural, and blended yarns.

Produces stable and strong fabrics compared to weft knitting.

Capable of intricate designs and patterns.

Applications

Apparel: Lingerie, sportswear, swimwear.

Home textiles: Curtains, nets, lace fabrics.

Industrial uses: Coated fabrics, automotive textiles, geotextiles.

Medical textiles: Bandages, compression fabrics.

Advantages

High productivity and efficiency.

Fabrics are dimensionally stable and do not ladder easily.

Wide variety of designs possible.

Suitable for technical and industrial textiles.

Limitations

Machines are expensive.

Fabric designs depend on guide bar movement (less flexible than weft knitting).

Requires skilled operation and maintenance.