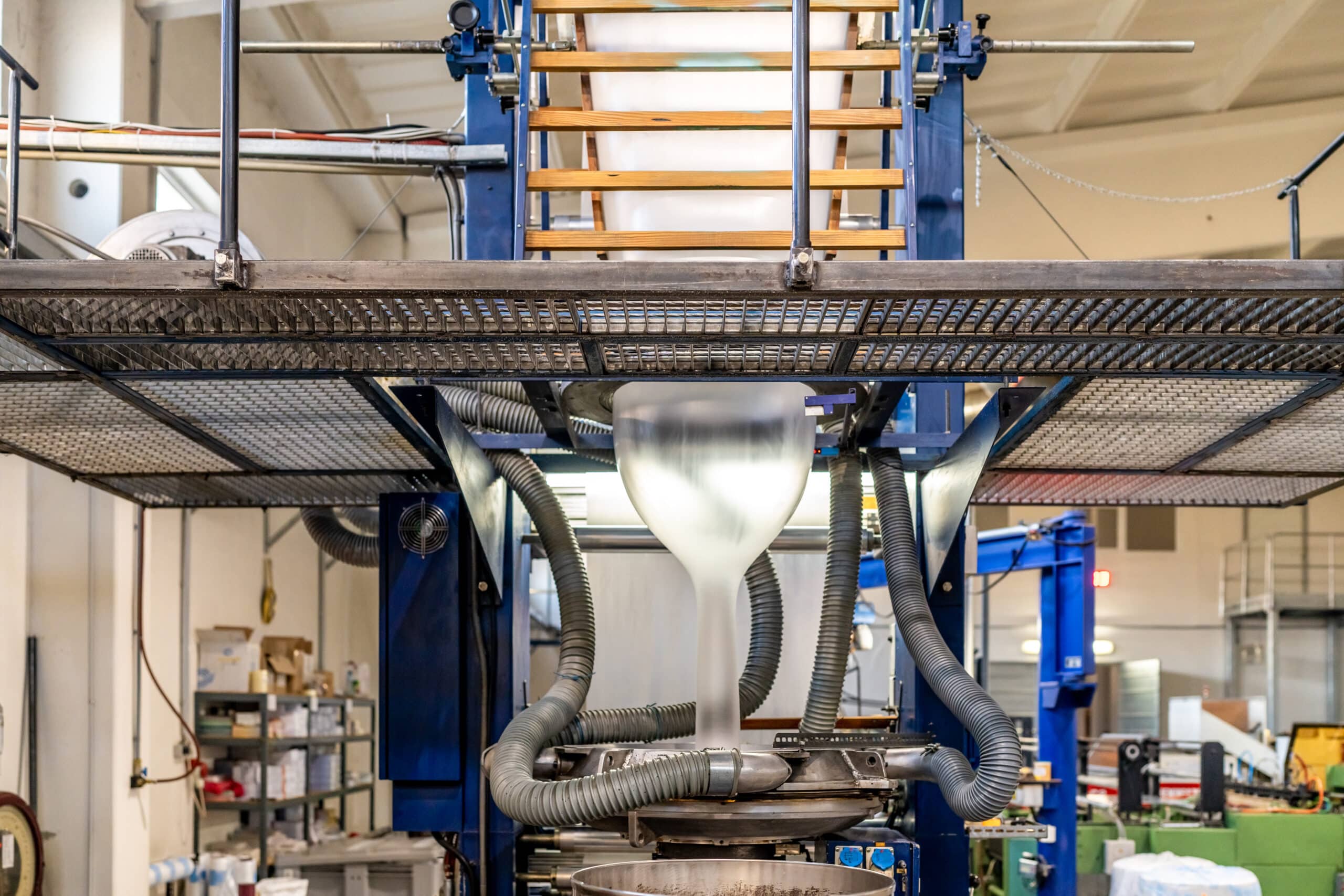

Blown Film Extruder

Definition

A blown film extruder is a plastic processing machine used to produce thin plastic films by extruding molten polymer and inflating it into a thin tube (bubble) which is then flattened into rolls.

Applications

Used for making plastic bags, packaging films, agricultural films, shrink films, and laminating films.

Basic Working Principle

Plastic granules are fed into the extruder.

Material is melted and homogenized by a rotating screw inside heated barrels.

Melt is forced through a circular die to form a thin tube.

Air is blown into the tube to inflate (bubble formation).

Bubble is cooled and collapsed by rollers to form a flat film.

Main Components

Hopper – stores raw plastic pellets.

Extruder screw & barrel – melts and pushes material.

Heaters – provide controlled heating zones.

Die head – circular die that shapes molten polymer into a thin tube.

Air ring / Blower – cools and stabilizes the film bubble.

Haul-off unit – pulls film upward and controls thickness.

Collapsing frame – flattens the bubble into two film layers.

Winder – rolls the finished film.

Materials Used

Commonly: LDPE (Low-Density Polyethylene), HDPE (High-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), PP (Polypropylene).

Film Characteristics

Thickness range: usually 10–200 microns.

Width: depends on die size and bubble ratio.

Properties: flexibility, transparency, strength, and moisture resistance.

Process Control Parameters

Temperature control – critical for proper melting.

Blow-up ratio (BUR) – ratio of bubble diameter to die diameter; affects film strength & properties.

Line speed – determines thickness and uniformity.

Cooling rate – controls film clarity and mechanical strength.

Advantages

Continuous and cost-effective process.

Produces uniform films with good mechanical properties.

Can produce very thin films.

Suitable for large-scale production.

Limitations

Requires skilled operation.

Limited to thermoplastic materials.

Film thickness control can be challenging.

Slower compared to cast film extrusion for very thin films.

Industries Using Blown Film Extrusion

Packaging (food, consumer goods, industrial).

Agriculture (mulch film, greenhouse film).

Medical packaging.

Shopping and garbage bag manufacturing.

Definition

A blown film extruder is a plastic processing machine used to produce thin plastic films by extruding molten polymer and inflating it into a thin tube (bubble) which is then flattened into rolls.

Applications

Used for making plastic bags, packaging films, agricultural films, shrink films, and laminating films.

Basic Working Principle

Plastic granules are fed into the extruder.

Material is melted and homogenized by a rotating screw inside heated barrels.

Melt is forced through a circular die to form a thin tube.

Air is blown into the tube to inflate (bubble formation).

Bubble is cooled and collapsed by rollers to form a flat film.

Main Components

Hopper – stores raw plastic pellets.

Extruder screw & barrel – melts and pushes material.

Heaters – provide controlled heating zones.

Die head – circular die that shapes molten polymer into a thin tube.

Air ring / Blower – cools and stabilizes the film bubble.

Haul-off unit – pulls film upward and controls thickness.

Collapsing frame – flattens the bubble into two film layers.

Winder – rolls the finished film.

Materials Used

Commonly: LDPE (Low-Density Polyethylene), HDPE (High-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), PP (Polypropylene).

Film Characteristics

Thickness range: usually 10–200 microns.

Width: depends on die size and bubble ratio.

Properties: flexibility, transparency, strength, and moisture resistance.

Process Control Parameters

Temperature control – critical for proper melting.

Blow-up ratio (BUR) – ratio of bubble diameter to die diameter; affects film strength & properties.

Line speed – determines thickness and uniformity.

Cooling rate – controls film clarity and mechanical strength.

Advantages

Continuous and cost-effective process.

Produces uniform films with good mechanical properties.

Can produce very thin films.

Suitable for large-scale production.

Limitations

Requires skilled operation.

Limited to thermoplastic materials.

Film thickness control can be challenging.

Slower compared to cast film extrusion for very thin films.

Industries Using Blown Film Extrusion

Packaging (food, consumer goods, industrial).

Agriculture (mulch film, greenhouse film).

Medical packaging.

Shopping and garbage bag manufacturing.